Norwood, MA. May 12, 2017. RemtecInc. (www.remtec.com), the leading manufacturer of ceramic substrates, packages and submountsusing PCTF®(Plated Copper on Thick Film) metallization, has added gold tin plated Ceramic Combo Lids to its line of ceramic SMT packages. Now designers can complement a full line of hermetic, ceramic SMT substrates and packages with high reliability gold tin plated

Norwood, MA. May 12, 2017. RemtecInc. (www.remtec.com), the leading manufacturer of ceramic substrates, packages and submountsusing PCTF®(Plated Copper on Thick Film) metallization, has added gold tin plated Ceramic Combo Lids to its line of ceramic SMT packages. Now designers can complement a full line of hermetic, ceramic SMT substrates and packages with high reliability gold tin plated

Remtechas developed a proprietary technique combining PCTF metallization and gold tin plating to produce the high reliability Ceramic Combo Lids. Remtec’sCombo Lids provide labor savings via the elimination of manual preform attachment, especially on small profile applications. In addition, an unique gold tin plating technology greatly reduces the amount of solder voids common for lids with tack-welded gold tin preforms, thus resulting in higher production yields.

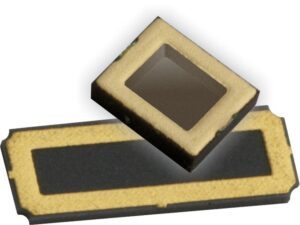

Remtec’sCeramic Combo Lids are available in two types: a flat gold tin plated lid and a five-sided box or “cavity lid”. Both styles exhibit excellent void-free soldering ensuring full hermeticitywhen used with high reliability hermetic substrates or packages. Remtec’sproprietary manufacturing process provides uniform gold tin flow and the ability to vary the thickness according to the needs of the application. Remtec’sceramic lids meet military standards and are available in prototype, small lot, and production quantities.

The applications for Remtec’snew gold tin plated Ceramic Combo Lids include military, aerospace, avionics and high reliability electronics.

Remtec, a RoHS compliant, ISO 90001:2008 registered and ITAR compliant company, operates a manufacturing facility (totaling 33,000 sq. ft.) in Norwood, MA. Remtecproduces custom and semi-custom packaging solutions for sensors and detectors, RF/MW products, DC power electronics, optoelectronics and other high density and power circuitry in commercial, industrial and military industries.