News & Events

Stay up-to-date

Remtec shares time-lapse video of new Canton, MA facility construction in progress

Remtec is pleased to share this brief time-lapse footage of the progress being made at our new Canton, MA facility

Remtec enlists NWN, Inc. to assist with M&RF clients in Northern California & Northern Nevada

Remtec today announced it has allied with NWN, Inc. of San Jose, California to develop and maintain business opportunities on the West Coast, with a focus on the microwaves and RF sector. A well-regarded and respected manufacturers' representative firm, NWN, Inc. was...

Remtec shares intro slidedeck for IMS 2023

In conjunction with Remtec's participation at the International Microwave Symposium (IMS) 2023 exposition in San Diego, CA (June 13-15), we are pleased to share this introductory slidedeck -- summarizing our capabilities, value, and product offering as it relates to...

IEEE IMS International Microwave Symposium 2023

IEEE IMS International Microwave Symposium 2019

Booth 237

June 4-6

Boston Convention Center

Boston, MA

APEC 2023

APEC 2019

Booth 235

March 18-20

Anaheim Convention Center

Anaheim, CA

SPIE Photonics West 2023

SPIE Photonics West 2019

Booth 5570

February 5-7

Moscone Convention Center

San Francisco, CA

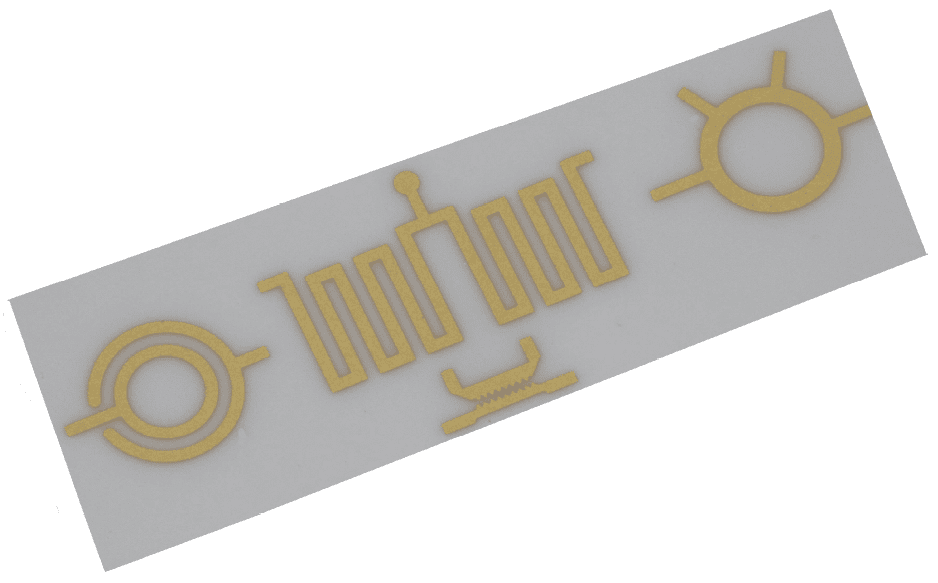

Remtec Introduces High Definition Etchable Thick Film (HDTF) Gold Process on Ceramic

Norwood, MA. February 15, 2018. Remtec Inc. (www.remtec.com) the leading manufacturer of ceramic substrates, packages and submounts using PCTF® (Plated Copper on Thick Film) metallization, has commercialized etchable gold thick film process for High Definition Thick...

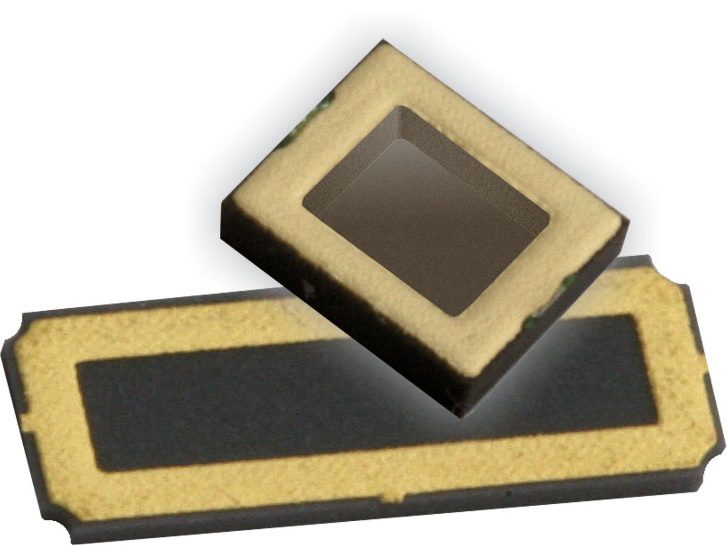

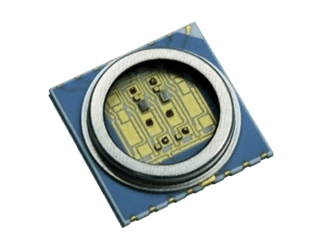

Remtec Adds Gold Tin Plated Ceramic Combo Lids to Complement its Ceramic SMT Packages

Norwood, MA. May 12, 2017. RemtecInc. (www.remtec.com), the leading manufacturer of ceramic substrates, packages and submountsusing PCTF®(Plated Copper on Thick Film) metallization, has added gold tin plated Ceramic Combo Lids to its line of ceramic SMT packages. Now...

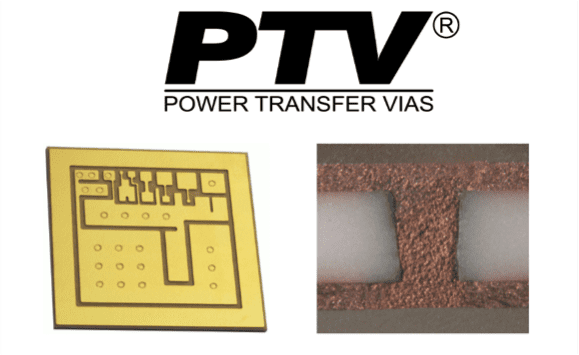

Remtec Expands Power Transfer Via (PTV) Technology To DBC Substrates.

Norwood, MA. March 24, 2017. Remtec Inc. (www.remtec.com) the leading manufacturer of ceramic substrates, packages and submounts using PCTF® (Plated Copper on Thick Film) metallization, has expanded its enhanced Power Transfer Via (PTV®) technology to Direct Bond...

Remtec and LTI Merge Metallized Ceramic Packaging and Glass-To Metal Packaging Capabilities to Expand Product Offerings to Sensor Markets.

Remtec Inc. (www.remtec.com), the leading manufacturer of ceramic substrates, packages and submounts using PCTF® (Plated Copper on Thick Film) metallization, has merged its metalized ceramic packaging capabilities with the glass-to-metal packaging capabilities of parent company, LTI (www.legacytechnologies.com).